The

Ariens 1960's and 1970's

PROUDLY

MADE

Replacing engines on older snowblowers.

|

|

As we know, the 1960's and 1970's Ariens Sno-Thros are considered very robust machines.. many of them are still running today! 30, 40, and even 50 years after they were first made! For 98% of these machines, they came new with Tecumseh engines (a small percentage of 1970's machines had Briggs & Stratton engines when new)..While Tecumseh engines are considered fine and reliable engines, if taken care of properly, (same as anything else), its just a fact that a 40 year old Tecumseh engine might not be quite as healthy as the 40 year old snowblower its mounted on! Engines often wear out faster than the snow blower itself..they have a lot more moving parts, that move much faster. This results in some otherwise serviceable 1960's and 1970's Snow blowers that simply need a new engine! A few guys out in snowblower discussion-forum land have posted threads about putting new engines on their old machines..and a few guys have emailed me photos and info about their conversions, and have allowed me to share their stories here! Thanks! so below are some "engine swap" storys.. |

|

A note on engine swaps..you cant just slap any engine on any snowblower! it needs to be a close match to the horsepower of the original engine, otherwise modifications of pullys and belts may be necessary if you are going to an engine with more HP than the original engine.. I make no claims about *how* to do an engine swap, I am only providing some experiences. It's up to you to research your particular snowblower model, and make sure the new engine you choose is fully compatable..and compability means much more than just "do the bolt holes match?" |

|

If you are interested in reading it, I moved it here. (Its about Chinese Honda Clones) So, a list of engines.. I would like to create a list of quality late-model engines, (or even older engines, like maybe late-model Tecumseh engines from the last 10 years or so) that can fit older 1960's and 1970's snowblowers..(doesnt even have to be Ariens either! if someone re-powered any vintage snowblower, regardless of brand, I would like to hear about it!) I will list any engines here that will work. Someday I would like to repower my 1971 Ariens..Ideally I would like to use an American Made engine, a Briggs or a Tecumseh..So im going to start a database here on this page, listing engine model numbers, and the machine model numbers that we know the engines been sucessfully installed on. If you have anything to add, please let me know! You will find nothing on this page about Harbor Freight engines, because I cant stand them and I think they are horrible. If you are considering a Harbor Freight engine swap, please read the stories below and consider if you might be able to use a US-made engine instead. Lots of good engines are still out there! It isnt necessary to go the cheap route! ;) better options do exist. |

|

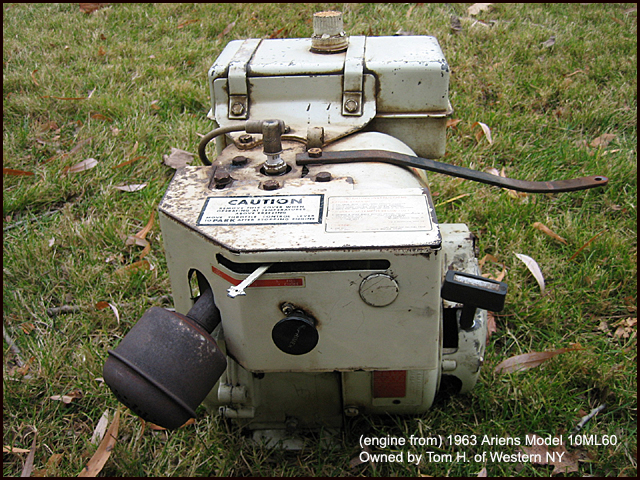

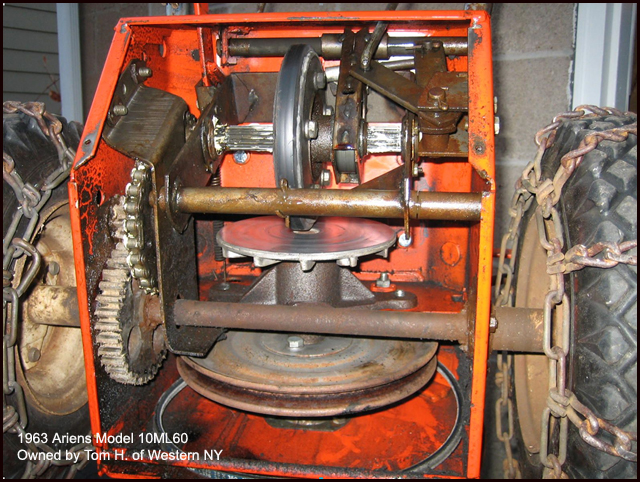

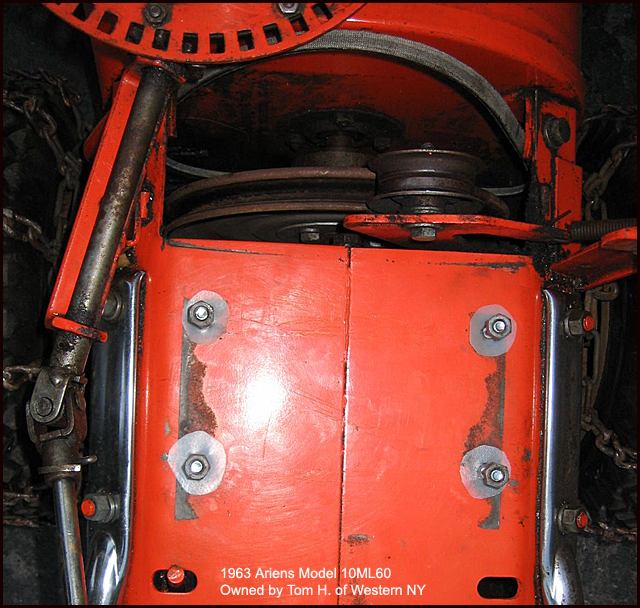

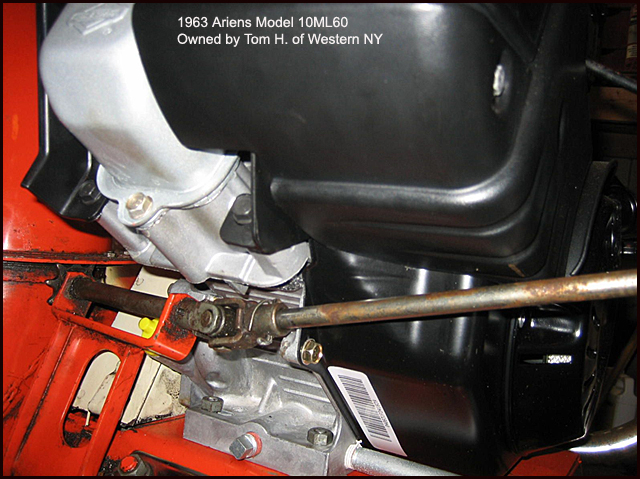

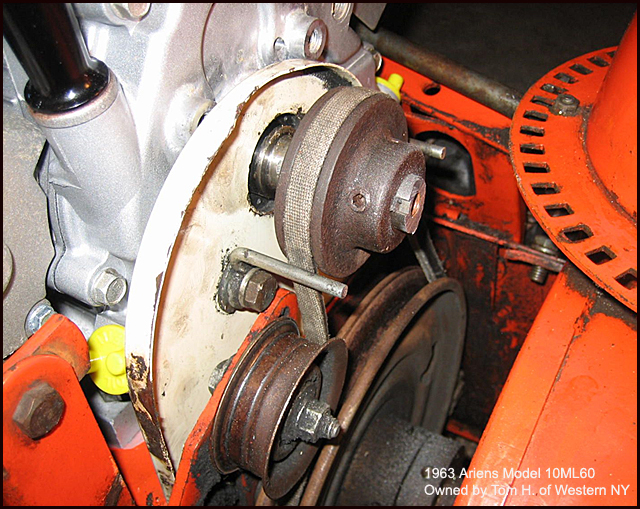

First up is an engine swap on a 1963 "First series" machine. This machine is owned by Tom H. of Western NY. Its a 1963 Model 10ML60, serial 31766. Tom emailed me a detailed account of his engine swap experience, which he did in 2009. Here is Tom's story in his own words: "I stumbled on to your site as I was looking for information on fixing my Ariens that wasn�t going on high speed when I got it started this Fall. It has always started and run with no problems except an occasional carb adjustment. I ended up taking the carb off and having a dealer clean it and check it out. When I reassembled the carb to the machine I still had the same failure to go to high speed. I have decided to purchase a 7.75 hp Briggs and Stratton with electric start from Small Engine Warehouse. I have become an older gentleman now and my wife also uses the machine. I felt that going for a new engine with electric start will lengthen the service of the 46 year old machine a couple of decades and also save some aches and pains for the owners. I bought the Sno-Thro over 20 years ago from another older gentleman that had taken very good care of it. I didn�t realize it was from the early 60s until I purchased gear box grease at a dealer. They looked up the serial number on the microfiche (remember those?) The machine has only needed regular maintenance along with a couple of belts and a left wheel bearing that fell apart a couple of years ago. The drive jaws also separated once. I take good care of my stuff and the Sno-Thro has the benefit of being kept in a walk out basement. That helps keep the rust away. The pictures show the current good condition of the machine. I will probably try to sell the old engine. I will send a picture when I install the 7.75 hp engine. Happy snow fighting, from a fellow Western New Yorker. Tom H."  With the original engine.   Original engine removed. Tom then emailed me more photos and a report on what he did to swap the engine. Tom continues: "I was looking for a way to fix my old Ariens (6hp Tecumseh H60) first series that wasn�t going on high speed when I got it started this Fall. It has always started and run with no problems except an occasional carb adjustment. I ended up taking the carb off and having a dealer clean it and check it out. When I reassembled the carb to the machine I still had the same failure to go to high speed. I thought that it was probably a good time to replace the engine rather than spend money and time chasing remedies. I also wanted an engine with electric start. I decided to purchase a 7.75 hp Briggs and Stratton with electric start. I have become an older gentleman now and my wife also uses the machine. I felt that going for a new engine with electric start will lengthen the service life of the 46 year old machine a couple of decades and also save some aches and pains for the owners.  Above is the old engine that I will replace with the 7.75 hp Briggs and Stratton engine. The experience was overall positive. I needed to drill the existing engine mounting studs out because they are only �� long. The base of the new engine is �� thick. I had some difficulty getting the new bolts in due to tight areas around the chassis drive components.  The drive components look like they are from an Army Tank. No wonder the machines last forever. You can see the heads of a couple of the new bolts. The new bolts are 1 ��. I would go for 1 � � If I did it again. How to keep the new bolts in place so they don�t fall though as I am trying to install the engine? I cut some round pieces out of a plastic milk bottle to make bolt retainers. I cut a small square in the center of the make shift washers and put slits around the squares so that the washers would act as nuts to keep the bolts in place. This worked fairly well. I had to tip the Sno-Thro forward to push one of the bolts back up through with a screw driver to clear the top of the engine mount base.  I was concerned about what would happen with the snow chute control rod. Some Old Ariens machines have a control rod that rides in a low position. Other machines have a control rod that is straight and angles steeply to an eye bolt on the handle. The first series machines are in the middle of these extremes. I was able to bias (loosen bolts and twist clockwise) the mounting bracket located by the chute to gain clearance of the chute control rod u-joint at the left side of the engine. I also needed to move the handle bar eyebolt down and to the left to allow the rod to miss the rear of the engine. I am O.K. with the result but this may be a problem for a tall person. I am about 5� 6� and I needed to bend down a bit to reach the control rod in the original position. Now I need to reach a little lower and to the left. Some people may have a problem with this modified position, but at least it is a viable option.    The third issue I dealt was an engine drive shaft interference with the drive belt cover. I think the new engine sits a little further forward than the old one. I decided to remove about �� from the shaft length. I thought it would be a pain to hacksaw through the shaft but I actually got it done in a few minutes.  My one big surprise was discovering that the new engine has no throttle control. I was a little disappointed because I feel that I would like some control over engine speed. I don�t think this will be a problem since when you run a snow thrower you usually run it fast to keep the speed up for the augers. I removed the throttle control lever from the handle bar and I am considering putting an engine kill switch in its place. The engine number is 12C113-0251. I bought it from Small Engine Warehouse. I looked at new Ariens machines at Home Depot. They have the same type of engine but with a throttle control on the engine, but not on the handle bars. I think the fixed throttle engine may be for the California market. The fixed throttle is considered a low pollution engine. I actually haven't started mine up yet. The engine has a red key that locks out the circuit. The key was not in the box. I could have stuck a piece of plastic in as an override. I called Small Engine Warehouse and they are sending me the key. I will let you know if there are any run problems.  The photo above shows the finished job. I now have a refreshed machine with electric start. The cost of the new engine was $272.00. Not bad when you consider a new machine would set me back around $1000.00. I also recently sold the old motor for $50.00. Sorry to see it go, but that�s life. Bring on the snow! I am ready." - Tom H. Wow! great job Tom, as you said, its ready for several more decades of use! thanks for sharing. |

|

Here is a nice engine swap on a 1969 model 10970. This machine was given a new 2003 Briggs 7.5 engine, and is owned by Bill C. of Pennsylvania: Hi Scot, Great website. Found you with Google looking for Ariens info and parts ect. I have a 1969 tractor model 10970 sn.002287 and an Sno Thro attachment 1970, model 10995 sn. 003073. It was given to me by a neighbor after the engine sized due to a lack of oil. I removed the head and saw the cylinder bore was badly scored. Since the machine was in good shape and looked nice (chromed bars) good tires, and very little rust, I decided to replace the engine. I ordered a B&S Intek 7-1/2 hp.snow blower engine. That was five years ago, and it has worked out well. We don't generally get huge storms in South Central Pennsylvania, but every few years there is a big one, 24 inches. I replaced the engine in 2003 after my neighbor sized up the original Tecumseh 6 hp. Snow King, and gave me the machine. The rest of the story is he went out and bought a new $2000 John Deer. It is a 2003 7-1/2 hp B&S Intek model 12D413. The throttle control is a lever on the engine. This lever also functions as a kill switch. After five seasons of use it has performed very well. Thanks to your website I was able to download a manual, and finally see the factory recommendations. As I said, I recently replaced the scraper bar, drive belt and idler pulley and changed the gear case oil again. Let me know if you need any further information. Regards, Bill     thanks Bill! |

|

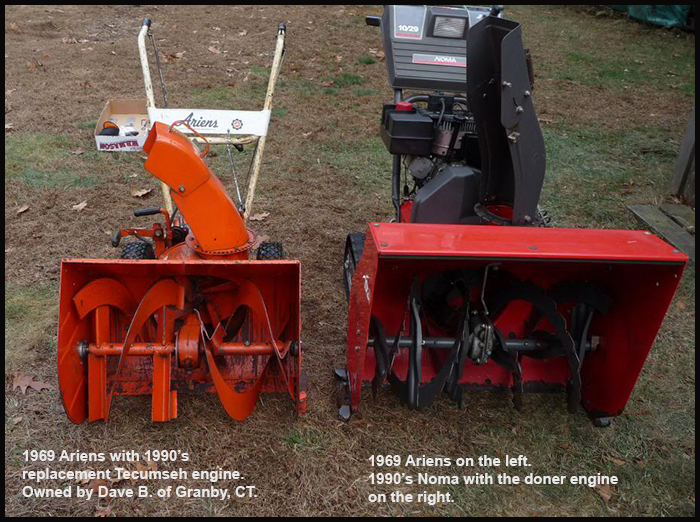

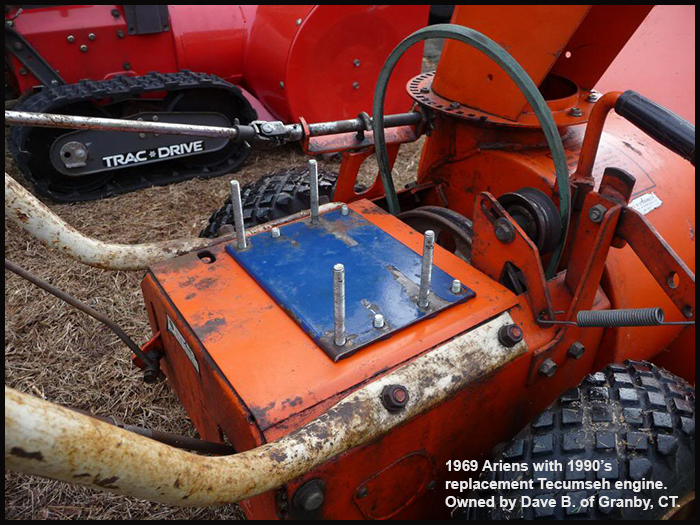

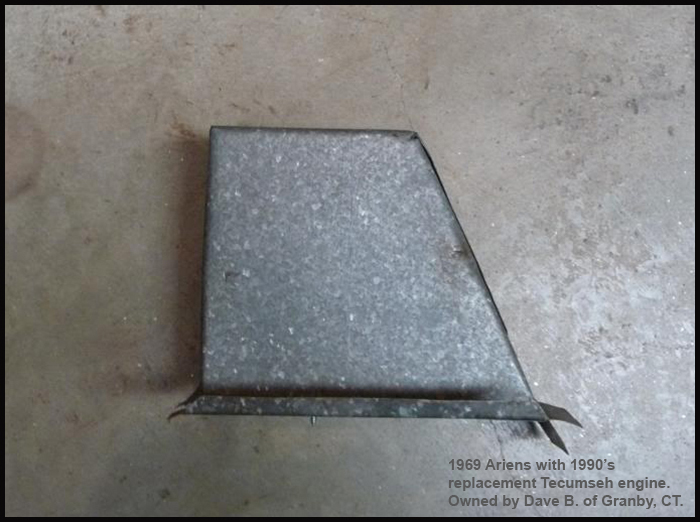

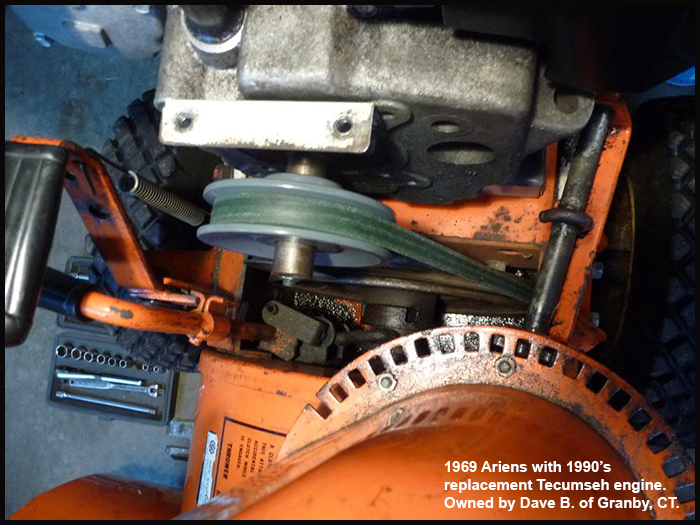

Here is a second 1969 Ariens with a replaced engine. This engine conversion was done by Dave B. of Granby, CT. Dave took a 10hp Tecumseh from the 1990's Noma and placed it on his 1969 Ariens, which originally had a 5hp Tecumseh. Here is Dave to share his story: Hi Scot, Thank you for adding my 1969 Ariens to your engine swap section. The formula is simple: Take a large engine from a large 300 lb blower and swap it onto a medium size 200lb blower. What are we building here? Muscleblowers? The 10 HP engine plus the larger 3" drive pulley turns the old Ariens into a snow eating tiger. This unit is eager now and you have to restrain it at times! 10 HP, 29", track drive 1994 NOMA donor blower. What a miserable handling beast. It does not have skid steer. Unstoppable in a straight line:    Size difference between Ariens and NOMA:    1969 5 hp, 24" Ariens with .25" x 6.5" x 9" motor mount adapter plate, 5/16-18 threaded holes 8 places. 4 ea 5/16-18 x 1" steel bolts, 4 ea 5/16-18 x 4" all thread steel bolts. Some filing required underneath deck for clearance to insert the long bolts:   NOMA 1" thick motor mount pad plus 2 ea .25" thick aluminum shims. Total height of these plus motor mount plate is 1.5".  I've also used polyurethane coated plywood as shims for raising engines 1.5" above stock with good results. The wood actually dampens some engine noise. Before you discount wood, remember some very powerful outboard boat engines are clamped onto wood covered transoms.  10 HP Tecumseh engine fastened down with stop nuts. Stop nuts need be checked for torque every few hours of run time for the first 6 hours. Always a good idea to check motor mount nuts for torque every season.  Ignition shut off ground connector clears chute driveshaft:  Throttle lever clears chute driveshaft:  Longer than stock drive shaft eyebolt in stock location in crossbar. Eyebolt centerline 1" lower than stock:  Stock 3/8" x 2.5" cast iron drive pulley on left. McMaster-Carr 6294K19 1/2" x 3" cast iron pulley with .75" bore and standard keyway. $20 with shipping. This pulley is for a 1/2" or 5/8" belt. With the 1/2" belt it becomes a deep groove 3" pulley, which is an advantage for this application:  3" pulley increases the fan speed and drive speed 21%. Fan tip speed increase from 34 mph to 41 mph. First gear now goes like 2nd gear used to, and top speed is a quick walk. 313 A 1/2" x 40" Kevlar wrapped heavy duty V belt is used. The belt is a lot less prone to slipping on larger 3" pulley because of increased contact area. The belt doesn't slip and the 10 hp engine doesn't bog. Increased drive platter rpm caused automatic up shift from 1st to 2nd to 3rd to 4th. Stock gear detents in shifter control on right were not deep enough to keep selector pin from camming out to next detent. Quick work with a rat tail file deepened and angled the detents forward to lock in selector pin of modified shifter control on left:  I folded up used galvanized duct work sheet metal to produce 2 piece belt cover:     338-343 Belt cover attaches to two 1/4-20 tapped holes in angle bracket bolted to engine with two 1/4-20 x 1" bolts and washers. Also a good view of installed drive belt with idler engaged and disengaged. Notice extra deep pulley so belt can't come off pulley when idler disengaged:     Belt cover installed:   View from controls:  Finished swap.     Operational notes: Not a good idea to pop clutch in 3rd or 4th gear at full rpm on dry pavement: unit will try to tip back very quickly and/or jump out of your hands. No dead man clutch on these old units so if it takes off on you it will keep going until someone catches up and shuts it down or it hits something. It takes about half the time to blow a 12" snowfall out of my driveway with 10 HP and the 3" drive pulley. First pass out the driveway in 12" of snow in 4th gear it plows what it cannot blow. It actually creates a bow wave of snow. When I get to the street it rams through what the street plow packs into my driveway, even if it is 24+" deep. Actually disappears under the surface for a while as it bores through and pushes out what it doesn't have time to blow. I'm using less fuel for the same job, and the 1994 engine burns much cleaner than the old 1969 Tecumseh: you can smell the difference. Raising the engine 1.5" over stock allows proper drive belt geometry with the 3" drive pulley and the stock idler pulley. It also allows the chute driveshaft to nicely fit under the throttle lever and the ignition ground connector. Keep the Idler pulley well oiled as it spins a lot faster now. 9" stock driven pulley is wide enough to accommodate a 1/2" wide drive belt. I do not like the 1970-up worm drive chute control: too slow and the chutes have a tendency to fatigue and break in half where they attach to the blower body. Plus the worm drive driveshaft doesn't clear swapped engines as well as the early sprocket drive driveshaft with u-joint. Fortunately the early Ariens sprocket drive and chute can be easily retrofitted to worm drive Ariens snow blowers. I grew up jockeying these Ariens snow blowers around large driveways with some heavy snowfalls. I love the balance and handling of these relatively lightweight blowers, and the clutch, shift, and chute controls are second nature to me. I always wanted more power for heavier snows and a faster fan for further snow throwing distance. Now I've got what I wanted and am very happy with the results. Have fun if you build one like this, but be careful as it wants to get away from you and can require more muscle input to control than a 5 or 6 HP engine. Grab onto those hand grips and growl when you use this thing. Best regards, Dave thanks Dave! :) |

|

Next up is a later 10,000 series, a 1970 model. Owned by "Garandman" This is one of finest "full restorations" of an old Ariens I have seen! Not only was a new briggs engine installed, but the whole machine was also restored! A very nice job:  Garandman also restored a 1995 Ariens. |

|

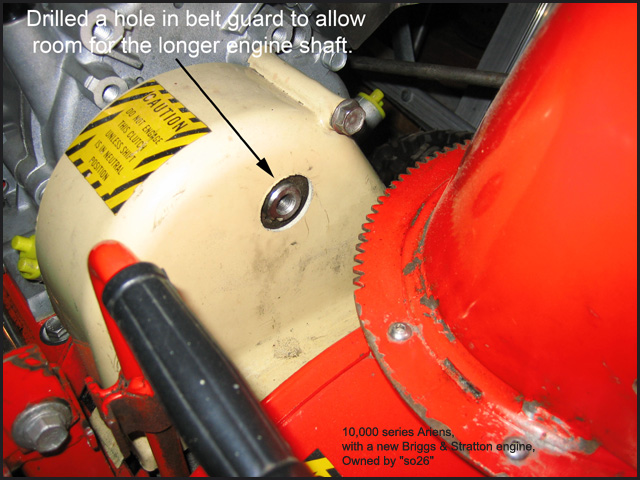

And here is another 10,000 series, this one has recieved the larger 9hp Briggs engine. Owned by "so26". This engine swap was done in 2008.    Some notes from so26: "The engine is model 20C400. The shaft height and diameter are identical to the original H70, however the shaft is longer and the mounting pattern is different. I have attached a photo showing how I dealt with the longer engine shaft:  I would say the following things are important when choosing an engine for the swap: 1) The shaft height should be the same otherwise a different belt length will be needed and this will increase the difficultly of the swap. 2) The shaft diameter should also be the same so the original pulley can be used. A replacement pulley can readily be purchased through online stores with different I.D. to match the new engine if needed. You will however want to keep the O.D. of the pulley the same otherwise again a different length belt will be needed. 3) The mounting pattern should be identical otherwise new mounting hole locations will need to be found. If the mounting pattern is identical to the original engine then you simply need to drill out the original studs and use longer bolts (flange bolts with lock nuts and washers are best) because the mounting flanges on these newer engines are thicker." - so26 More notes from "so26" concerning his 9hp briggs install. "By far the 15000 series Intek engines (e.g., 7-8.5hp) would have been easier to install, b/c the engine mounting hole pattern is the same as the H70. all that is required is to drill-out the existing studs (b/c they are too short) and replace with some longer flange bolts. However, I couldn�t find any 15000 series intek's on small engine warehouse that weren't stationary throttle. In addition, Snowmann has mentioned a few times that the 20000 models have a significantly better powercurve compared to the 15000 series. I was also able to get a very good deal on it and who doesn't want more power?" "BTW, this engine is 305cc compared to the 250cc used on the 7-8.5hp models." quote from the thread linked below. Another great engine swap! thanks Sean! |

|

Here is a very nice engine swap and snowblower restoration on a 1972 10,000 series, using a modern (2004 - 2008) 7hp Tecumseh Snow King engine. This machine is owned by Kevin Q. of Pompey, NY. Here is Kevin to tell us about it: Scot, Saw your website, so i took action.... Was: 1972 Ariens w/ blown engine rusting away in my shed. Is: Restored to original condition w/ engine swap. New bushings, bearings, friction disc, springs, roll pins, cotter pins AND original mint condition 1972 metal hub caps w/ gear logo found at a company in Maine sititng in parts bin for 35 years.. Heres' info on engine: 7hp Tecumseh Engine Snow King OH195SA-72566 7 HP. purchased from Small engine warehouse. (note: engine does not have electric start) Modifications I did were: drilled out studs, (make sure you drill new holes in center of old studs for best alignment fitup) (used a hacksaw to cut off studs flat to tractor plate prior to drilling holes.) I used grade 8 bolts size 5/16-18UNF x 1 1/2"L & bought crank chute w/ universal joints found on 1980's Ariens 8 hp model ...(I took worm gear off the original straight chute rod and re installed on rod w/ universal joints, the angle of gears looked a little different). Kevin -- Pompey, NY      Thanks Kevin! |

|

Here is the final year of 10,000 production, a 1974 model 910018. (This machine is actually a hybrid of parts from several different machines.) This machine was re-powered by a late model (year 2005 or so) Tecumseh snow-king engine, from a junked MTD snowblower..(With old Ariens machines, the engines often last 30 to 40 years, but still wear out before the snowblower itself..with modern MTD's, the snowblower is often junked long before the engine wears out!) This machine was rebuilt and refurbished by Doug C. of North Ridgeville, Ohio.. here is Doug to tell his story: Scot, Good evening and thank you for putting this GREAT web site together. I was given a tecumseh LH358SA engine off a mtd snowblower and Iwanted to put it on my Ariens 10970 ,but after checking the things that I had to change I decided to look for a donor machine.I found a 910019 with a bad engine. I completely disassembled the entire machine, sandblasted and glassbeaded all the parts. I then sent all the sheet metal to the powder coater.The next step was to clean and glass bead all the nuts , bolts, brackets and linkage rods to get cad plated. I also drilled the impeller for a Clarence impeller kit. I changed the tires to the xtracs so no more rusty chains. I didn't like my chute bracket that I installed on the handle bars and I was looking on ebay and there was a 910018 case for 35.00 buy it now.I bought the case and transferd all the parts. So now I have a 910018 SER.NO.015144 and blower housing 910017 SER.NO.035107. Some things I had to do was cut the shaft on the engine,bore out the pulley to 7/8 and recut the keyway. I had to change the shaft which is in the friction wheel bracket to .530 to remove all the slop The normal size is .500 , I bored out the brackets and the case this made like it was brand new .I repaced all the bushings,some bearings.and used stainless nuts and bolts where I could.I love your web site ,I check it out all the time to see if added anything. I hope you like the pictures. Thanks, Doug C. North Ridgeville, Ohio      Thanks Doug! |

|

And here is a big model 924013 with a 924012 32" scoop. This is believed to be a 1974 model, although models 924010 and 924012 do not exist in any known Ariens records! But based on the model number itself, and the use of the earlier "teardrop" scoop (as opposed to the more common "924000 series" scoop) this is clearly a very early 924000 series, most likely from 1974. This machine has the same replacement engine as the 10,000 series above! It would appear late-model Tecumseh engines are good canidates for repowering older snowblowers..and the Tecumseh engines were all made in the USA!   This machine is owned by Steven W. of Port Hope, Ontario Canada. Steven recently aquired this machine, it had a blown engine when he bought it, so he installed a new late model Tecumseh engine, and had the machine repainted..Steven says: "Mr.Lawrence thank you for the great web site, it was a great amount of work and you did a beautiful job. I stumbled on your website. I have an Ariens snow blower with the model no.924012 and the serial no. 007178, I ordered a scraper blade for it, I waited over a month until it came and they sent just a flat straight piece ,I'm working with the no.924013 information, as 924012 does not even register, but is clearly marked on the machine white tag. I need the scraper blade with the bent ends that bolt back into the sliders, I got the machine because whoever owned it before got a newspaper caught in it and blew a hole through the side of the motor, I've done a lot of work to it, but I just love it .I do a lot of snow removal, we live in Port Hope Ontario Canada , every body comments on it, the next door neighbor calls it the corn chopper. Thanks again for doing this site. - STEVEN W." I then asked Steven if he would send me some photos! he obliged! "Hi scot, glad you like it, it was fairly easy to install providing you take some measurements with calipers, the old engine had a 3/4 in shaft and was approximately 4 inches long , so that's what I looked for ,this new motor isn't the greatest, meaning it is only rated for 250 hours but I got it at a steal because Tecumseh is finished in this country, as far as being on a snow blower anyway, so maybe these people putting new Briggs motors on these machines are worried about parts availability. The motor is a 11hp Tecumseh and is very strong, it can go through the absolute deepest snow with out even a grunt. Everybody I talk to says they don't really care for Tecumseh, they sputter an pop some times, but they have been on snow blowers for years, so even if this motor is rated for 250 hours with a little tlc should last a long time. Engine model LH358SA. the actual length of the shaft on the old motor was roughly 4 inches, could have been smaller, but bottom line measure everything before you go hunting. When I need parts again what number do you think I should use for the 924012? which does not exist. Im using 924013, like I told you the other day I just received a scraper blade with the 924013 number and it is different, it still lines up to the bottom holes but is missing side pieces. I made the pieces by hand and just have to weld them on',has to be a square hole to allow carriage bolts to slide for adjustment of scraper blade. Take CARE, STEVEN W." Thanks Steven! great job! |

|

Here is another 924000 series engine replacement, this one is a 1978 Model 924026. This machine is owned by Rob F. Here is Rob to share his story: Scot, I completed the restore of my Ariens 24" 924026 with serial #031899. It was originally purchased with an 8hp Tecumseh but I got a great deal on a brand new 11hp. I spent the better part of 2 months stripping it down and re-painting it and even found a place that reproduced the vinyl Ariens name and logo decals for me. I am attaching a couple of pictures if you are interested and you may also use them on your website if you'd like. Believe it or not, the engine was a direct bolt on replacement (I think the Ariens/Tecumseh gods were smiling upon me LOL). The new engine does have a throttle but no way of connecting the throttle control cable on the handle bars so it's just there looking pretty. I was able to wire in the key switch by cutting the wire on the engine where the orange plastic key goes, connecting the engine lead to one wire on the switch and the other switch wire to ground. That's about it LOL. It was a fun project and my second Ariens restore although I didn't do as much detail on the first as I did with this one. The model on the 11hp is OH318SA-221836-EP. It has provisions for electric start and has an alternator if I want to add a light kit. I did forget the other item I needed to get the engine to work was a shaft sleeve. The new engine has a 3/4" shaft while the original pulley is 1" diameter shaft. I had always wanted to do a re-power on my original mid 60's Ariens, but the lack of safety features (holding the clutch lever down to stop!) kinda drew me away. When I bought the 8hp I knew almost right away that it was going to be a re-power. I had also thought about re-powering my 70's 5hp 922 series but the engine has a aux PTO shaft and a new engine was insanely expensive. I'm surprised the cost of the Tecumseh's hasn't started to drop yet. I'm guessing they will when stock starts to get old and they need to move them. Take care. Rob    Thanks Rob, great job! |

|

Here is a great engine swap and restoration on a single-owner 1989 model 924050. This machine is owned by JP of Wisconsin, who bought the machine new in 1989. Here is JP to share his story: Hi Scot, I have read with interest all the great information on your website. I thought I�d tell you my story and send some pictures. I was interested to learn this design was first introduced in 1980. Feel free to use this information any way you want. This is my Ariens ST824 model 924050 snow blower. I am the original owner purchasing this machine new in March 1989. The serial number is 120216. This snow blower has served me well over the years however two major events have happened that I believe have made the present condition as good or better than when it was brand new. In winter of 2004-2005, after 15 years of service, the 8HP Tecumseh snow king engine suddenly became tight. I used the machine early in the winter. One day I needed to use it and I could not pull the recoil cord. The engine did not move. I was always religious with annual oil changes (5W-30) and checking the oil before each use. I was vaguely aware of Tecumseh�s propensity to throw connecting rods if oil level was low. I guessed I used the machine an average of 15 hours per winter. This would mean the engine failed after only 225 hours. I was at a crossroad; do I buy a new engine or buy a new snowblower? My father-in-law encouraged me not to trash this snowblower. My wife�s cousin is an engine technician for Briggs and Stratton. He fixed me up with a new B&S OHV Snow Maxx engine at a very good price. He installed the engine for me. He said the engine bolted on the tractor section with no issues at all. This new OHV engine runs much smoother and quieter than the old L-head engine while delivering similar power. Also in 2005, I had the bucket and chute sandblasted and repainted. My nephew works in a body shop so he did this for me. I painted the augers and impeller, but didn�t take this assembly apart. Last winter (2009-2010) I noticed erosion in performance. The machine didn�t throw snow and gobble up deep snow like it used to. Something was wrong. This past summer (2010) I split the machine and removed the bucket section. The bearing on the impeller shaft wiggled noticeably. This was culprit number 1 of my performance problems. I also noticed the impeller shaft wiggled noticeably from the gearbox end. This was culprit number 2. The augers were well greased and came of the shaft easily. I had to soak the roll pins attaching the impeller to the shaft with Kroil penetrating oil for a few days before I could drive out the roll pins. I also soaked the impeller where it meets the impeller shaft at both ends for about a week. I have a friend Frank who is a farmer and a skilled metal worker. He has a hydraulic press that we used to press the impeller shaft out of the impeller. There was some squawking and other scary noised, but the shaft was removed. After the impeller and augers were removed, I opened the gearbox and immediately found my problem. Both bushings supporting the impeller shaft were either cracked or broken in several places. Luckily, the pieces stayed where they were so the worm gears were not damaged. I got out my parts manual and ordered all the replacement parts I needed (all parts were readily available). While I had the gearbox apart, I also replaced the auger shaft bushings and seals. This was an easy job. I refilled with fresh Ariens gear lube and closed the gearbox. The impeller shaft was now nice and tight, but spun freely. As long as everything was apart, I decided to repaint the bucket, chute, impeller and augers. The only rust was a little on the edges of the augers so preparation for painting was simple. There was also paint worn off in the impeller cylinder and the inside of the chute. The augers, impeller and gearbox were sprayed with a coat of rustoleum white primer and two coats of rustoleum gloss black. The bucket and chute were painted with 2 coats of rustoleum white primer and 3 coats of valspar Allis Chalmers orange farm equipment paint applied with foam pads. Between each coat of paint I lightly sanded with a 3M superfine sanding pad. The finish rivaled spraying without the mess. Refinishing the wheels was not part of the 2005 repainting. I had the tires removed so I could sand and spray the wheels with primer and Rustoleum Gloss Almond. The wheels were rusty but cleaned up pretty well. Besides the rebuilt gearbox, a new impeller shaft bearing was installed during reassembly. I used grease or anti-seize generously during reassembly. On Dec 10-11 we received 8� of somewhat wet snow. This was the first test for my restored machine. The improved performance was impressive. I was throwing wet snow 15-20 feet. Powder snow should throw farther. Tightening up the drive train is transmitting more of the engine power to the impeller and augers. At age 21, I think this machine looks pretty good. I hope you enjoyed my story and can use this information to help all your website viewers. All the Best, JP     Thanks JP! beautiful job! |

|

Engines:

they are not necessarily (and very likely are not) the *only* years produced! |

|

Engine notes for Briggs & Stratton engines: Briggs & Stratton model numbers, (that relate to the topic of this page) and country of origin: 12C113-0251 - 7.75HP - Indonesia Briggs model 12C113-0251 (often used to repower vintage Ariens) made in Indonesia: http://www.smallenginewarehouse.com/product.asp?PN=12C113-0251 http://www.alibaba.com/product-free/107108451/Briggs_Stratton_Engine_ES_3_4_7_75hp_snow_blower.html Briggs & Stratton model numbers, and what they mean: Note from Briggs - http://www.briggsandstratton.com/maint_repair/BS_modeltypecode.pdf An interesting Briggs & Stratton resource: Technical Data for Early Briggs & Stratton Engines - http://www.asecc.com/data/briggs/ Not terribly relevant to snowblowers, since it seems to be about Briggs engines made from the 1920's through the 1940's..but still, could be useful to someone! A page about more recent Briggs engines and their serial numbers: http://www.outdoordistributors.com/Briggs_And_Stratton/briggsmodelid.html Concerning where Briggs & Stratton engines are made.. I have found some on-line references about the "Manufacturing plant" info hidden in the "date code" portion of the serial number, such as: CODE 01061201, The code is the manufacturing date and is read as follows: 01 - YEAR 06 - MONTH 12 - DAY 01 - ASSEMBLY LINE AND MANUFACTURING PLANT However, I have yet to find any information concerning which codes go with which Manufacturing plants! If anyone can help with this, please let me know! Update on Briggs engines and country of origin. In late 2010 (2011 model year for snowblowers) I came across some Briggs info concerning which engines are made where..This applies to 2011 (and recent earlier years) only.. things can change quickly.. Briggs engines used on 2011 model year snowblowers: Briggs & Stratton 205cc 900 series - Made in China Briggs & Stratton 249cc 1150 series - Made in China Briggs & Stratton 305cc 1450 series - Made in the USA Briggs & Stratton 342cc 1550 series - Made in the USA Briggs & Stratton 342cc 1650 series - Made in the USA This means that in 2011, virtually *all* entry level machines will have engines made in China. Either smaller Briggs (chinese) engines, LCT, or other brands, but all made in China. "Mid level" machines are still a mix..they might have a domestic Briggs, or Chinese engines, or Subaru engines, depending on the snowblower manufacturer and the "trim line" of the machine. But for the most part, In 2011, only the higher-end and Professional models still have the larger Briggs engines that are still made in the USA..(the 1450, 1550 and 1650 series Briggs engines are the ONLY snowblower engines still made in the USA in 2011.) Below are some other people's personal opinions on engines, from various forum threads..im putting these here for my own reference. im trying to research which Briggs engines are "better" and which are more "low end"..and which models are made in the USA vs. made in China. (the info below might not necessarily be factual! ;) sometimes people mean well, and think they know an answer..but they could be wrong.) "I think the remarks about the B&S engines might be a bit off the mark. I have a 305cc on my snow thrower and it's a damned good engine" "I agree. The 305CC B&S Snow series (Non Max series) engine seems to be a strong runner. Maybe not a fair comparison but I really don't find it much different in refinement to the GCV190 motor in my HRX217K2HMA Honda mower." two quotes above are from this thread. " Their (Briggs) Vanguard line is made in Japan by another company and is excellent." "Briggs Horizontal inteks are Made in China, have been for a few years. The Briggs Vanguard is made in Japan by Daihatsu, and some are rebadged as Mitsubishi Utility engines." http://www.mytractorforum.com/showthread.php?t=97009 "as best I know, all the 12XXXX come from the Briggs plant in Chongqing China. 15XXXX and 20XXXX still come from the US." http://www.perr.com/phpBB3/viewtopic.php?f=14&t=435&start=0 Briggs & Stratton official webpage: www.briggsandstratton.com |

|

A Major change rippled across the Snowblower industry in the 2009 model year. (winter of 2008 - 2009) This was the last year Tecumseh engines were regularily used on snowblowers! Tecumseh left the small engine market in 2008. Tecumseh leaving the market opened the floodgates for a new breed of engines made in China.. yes, snowblowers had already had Briggs engines made in China for a few years before this, (Briggs started making some small gas engines in China in 2002) but up until 2009, the vast majority of snowblowers still had Tecumseh engines on them. (All Tecumseh snowblower engines were made in the USA, right up to the end in 2008.) So for 50 years we had a long legacy of quality American-made snowblower brands, with quality American made engines on them (Tecumseh) resulting in a 100% American made machine. Sadly, even though many snowblowers are still being made in America today, many engines are now made in China..we have probably crossed over from 90/10 American/Chinese engines in 2008, to 50/50 by 2011..in another few years, it will likely be 10/90..and the way things are going..(I dont even need to say it..) In 2011, only higher-end models still have American made Briggs engines. (We do still have some 100% American made snowblowers! for now) But in 2011, probably half of snowblowers (from "entry level" to "mid level") all now have Chinese engines on them..(Briggs engines made in China, and other Chinese brands) The new LCT Chinese engines are believed to be of good quality, but many others (such as the Harbor Freight "Honda Clones") are believed to be of very poor quality.. So much so, I wont even discuss them on this Ariens repower page..I consider it blasphemy to put a Chinese honda clone on an Ariens..Its basically like putting a Hyundai engine in your restored 1969 Camaro..its just wrong on so many levels..you can find my rants elsewhere about that! ;) Tecumseh model numbers, and what they mean: "Are you aware of the Tecumseh serial number system? The first number in the serial represents the last digit of the year of manufacture, (you have to figure out the decade) and the last three digits correspond to the day of the year- thus serial 1321 was built on the 321st day of 1971. The John Deeres of the 60's and 70's were made by Bolens, and later ones by Ariens, The 1032 model you have pictured is a Bolens with what appears to be a later model Ariens hi-rise chute. Keep up the good work! Gary H." "Hi Scot- I have rebuilt 7 John Deere machines from 1971 to 1979, ( according to the Tecumseh numbers). One was identical to the one on your site. Mechanically, they are nearly identical to the Bolens machines I have also rebuilt. Some features are unique to JD, such as the huge gearbox. I don't know when the change to Ariens occured, but it was after 1979. Presumably this was because Bolens was bought by Gardenway and their snowblowers became Troy-Bilt. Of course in about 2000, MTD bought Gardenway and the Troy-Bilt snowblowers now are just cheap MTDs. I would like to add that overall, I would consider the 70's Ariens somewhat superior to the 70's JD-Bolens. For one thing, the JD engine mount area is not heavy enough, and every one I've had was cracked around the engine mount bolts. Additionally, where the small axle runs through the stub axle, there is no grease zerk like Ariens has and these are usually siezed and nearly impossible to get apart. Never had one stuck on an Ariens. Same thing goes for the auger halves, no zerks on JD and they are usually rusted solid to the shaft. Gary H." Thanks Gary! Some 2005 Model year Tecumseh engines recalled. (no model numbers listed, you have to go by the date code) |

|

About 2010, another major change happened in the engine arena.. Horsepower ratings no longer exist for snowblower engines! It seems the engine manufacturers might have been playing it a bit loose with HP ratings, and naturally (this being modern America) lawyers had to get involved..there was a lawsuit, and as a result, we no longer have HP ratings..now engines are only described in "cc" numbers. (cubic centimeters) or in "foot pounds of torque"..this makes things more difficult when trying to determine a new engine for an older snowblower! because you want to make sure the HP of the old and new engines are at least close. Roughly speaking, a new 205cc snowblower engine is approx 5.5HP. |

|

(this page is very much "in progress"..far from complete..) As I said, I have made this particular page because I might want to someday do an engine swap on my own 1971 Ariens, if the original Techumseh engine ever wears out to the point that its not worth fixing.. And since I want to gather all this information for my own engine research, why not share it all while im doing it? The *ultimate* engine conversion (for me personally) would be to find a replacement engine of the same (or similar, compatable) model, (an early 70's Tecumseh H70 in my case) in new or very good condition! In the classic car world they have parts called "NOS parts", meaning New Old Stock..these are "New", because they have never been used, but "Old", because they are original parts made in the 50's or 60's! for example, you can find a "NOS" 1965 Mustang fender! made by Ford in 1965, but not yet used..its a 45 year old brand-new part! Wouldnt it be amazing to find a "NOS" early 70's Tecumseh engine?! an H70 or H80.. very unlikely I know..but hey, anything is possible! Second best would be a vintage engine in used but very good condition. Third best (for me) would be a modern American made engine, Tecumseh or Briggs. |

|

Update on the

engine

situation! January 2013.

Looks like 2013 model year (machines that went on sale in the Autumn of 2012) will be the last year for a "100% made in the USA snowblower"! meaning both the snowblower body, and the engine both. (many snowblower bodies will continue to be made in the USA, from all the major manufacturers, but not the engines) Only a few Briggs snowblower engines were still made in the USA in recent years, but in 2012 that production stopped, and all production moved to China. For the full story and details, check out the forum discussion here: http://www.snowblowerforum.com/forum/general-snowblower-discussion/1364-made-usa-versus-made-china.html |

|

Continue

to

Page 11 - Some

Questions & Answers. |

This educational, non-profit

site is not affiliated with the Ariens Company.

It is simply the "hobby webpage" of

one satisfied 1971 Ariens Sno-Thro owner.

All logos, names and

trademarks are property of their respective

owners.

Official Ariens webpage is

here:

www.ariens.com

Scot Lawrence

Site started January

2009

This page last updated January 2017

For information about Ariens parts, see here.

For other general

snowblower questions,

take a look here:

http://www.snowblowerforum.com/

I am a member on that forum, and its a very friendly

and helpful place!

The best place for snowblower discussion on the

internet.

If you have questions, you can find the answers

there..