Page 2.

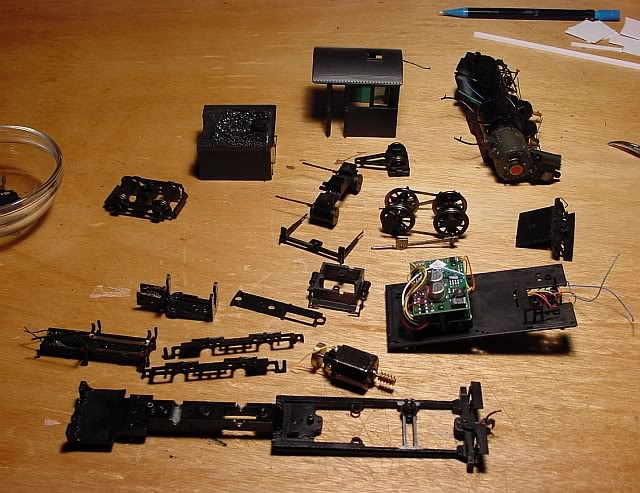

Deconstructing

the Forney.

January

25, 2008.

Lets take it apart

and see how things look..

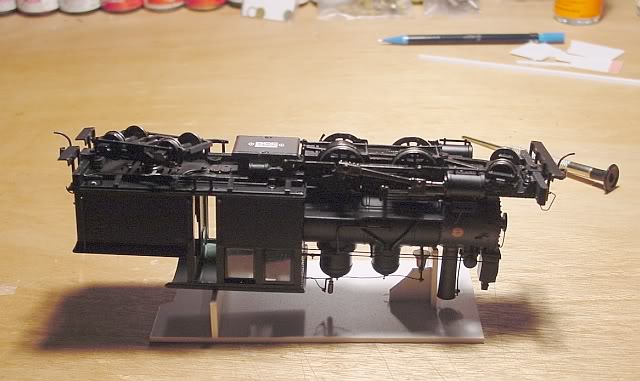

Homemade styrene

stand..makes things much easier!

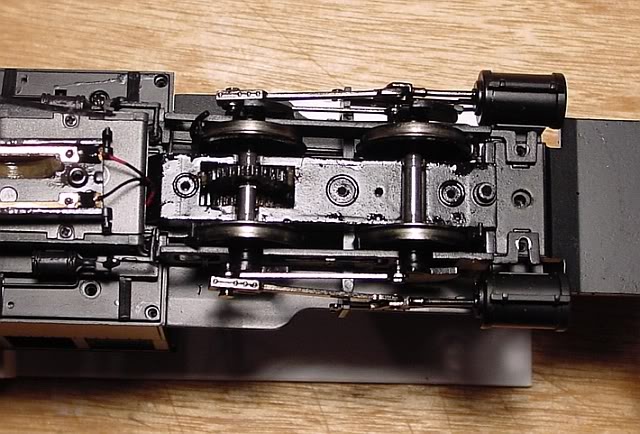

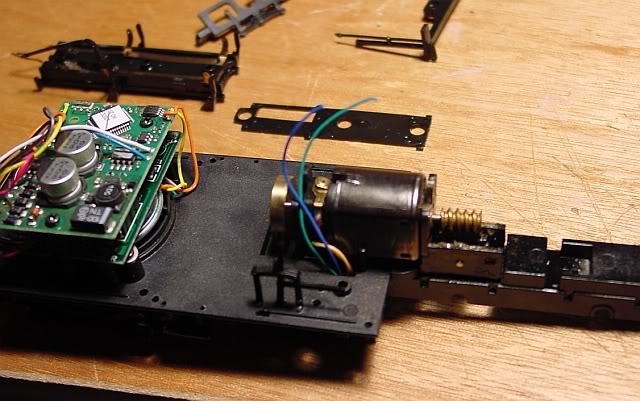

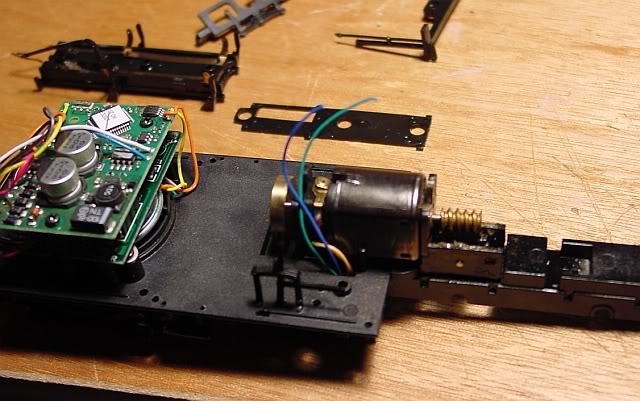

I really hate

to cut wires! I try to cut as few as possible..electronics is not my strong-suit!

and im always

afraid I wont be able to get it to work again! but I keep track of which

wires

go where, I've

done it before..shouldnt be a problem! I hope..

I also take these

"deconstructing" photos for my own reference!

so I can remember

what things look like when its time to put the loco back together!

(I have quite

a few more than what I have posted here)

Bachmann also

has a nice big "exploded diagram" of the forney on-line,

you can find

it here.

speaking of "exploded"..

Well..this is

still going to be difficult, but much easier than Number

23!

(which I have

put on hold for awhile..just becase I feel like working on No. 9 instead

right now..

I want to finish

a project before spring, and I think I can with No.9 but not with No.23)

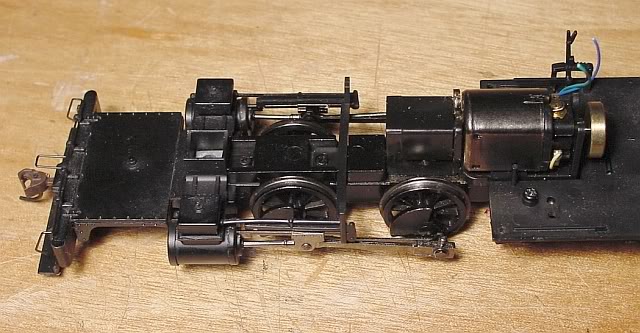

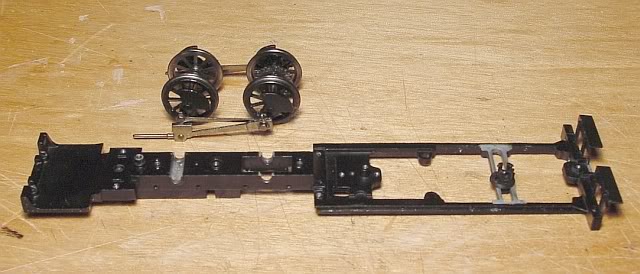

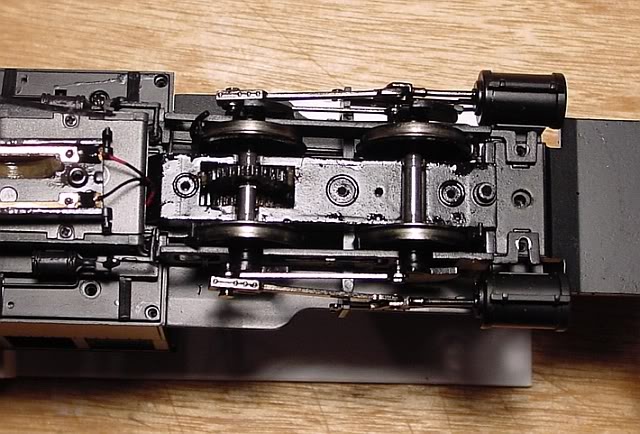

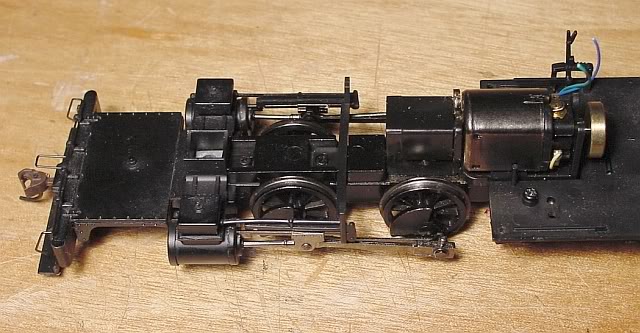

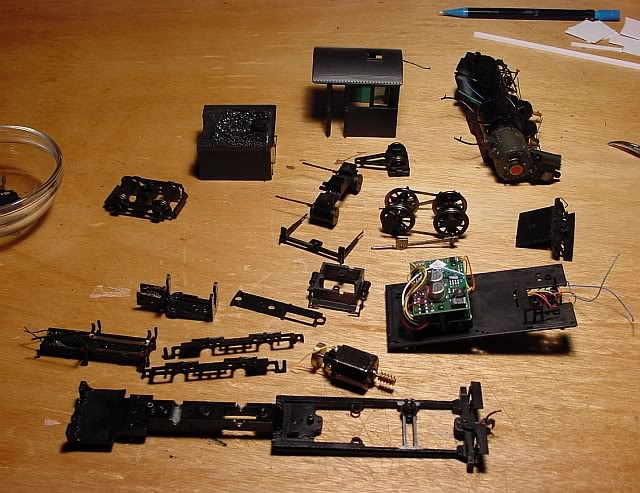

Two major areas

of concern..the frame and the drivers.

The frame is

about 2mm too wide! urrrrr...

just needs a

tiny bit shaved off each side.

(Dear Bachmann..in

the future could you please please make the frames narrow enough

for those

of us in On2?

please? thank you..)

Looks like enough

can be removed from the frames without compromising the frame axel cut-outs.

the question

is.. how?

the only model-making

powertools I have are a dremel tool, a drill press, and a mini power saw.

Im not equipped

for lathing or milling..

I think I will

simply take a dremel grinding bit to it!

its not elegant,

but it should work..

and I can still

use the axle notches..that will keep the axles aligned.

all I need to

do to the frame is create enough clearance..and I dont need much.

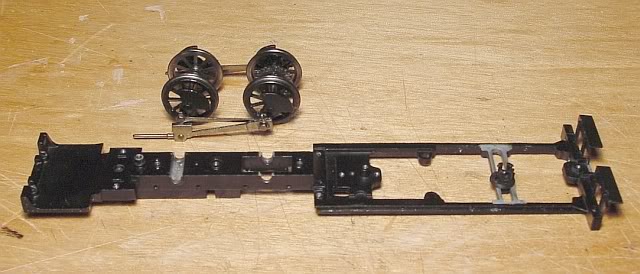

The drivers will

be the biggest problem..how to regauge them?

Here is a look

at what needs to be done:

(im not sure about

that gear placement yet..where the gear needs to be on the axle

when the regauging

is complete..need to look into that.)

On30 track gauge

is 16.5 mm

On2 track gauge

is 12.7 mm.

thats a difference

of 3.8 mm.

The smallest unit

of measurement I deal with is half a millimeter!

I dont divide

things any smaller than that..

So to regauge

from On30 to On2, wheels need to moved inward by 4mm.

thats the magic

number.

There are two

methods of regauging.

A.

cut the axle

and insert the ends into a new brass tube.

I did that sucessfully

with the

29n2 scale forney.

But that loco

is so much larger than these teeny tiny On30

locos!

(man..im

glad im not doing HOn2!)

the wheelset

without the gear wouldnt be a big deal..

but the wheelset

with the gear would end up with only a 4mm bit of tubing..

thats really

tiny. (im thinking of leaving the gear on its original axle, and only

cutting the axle

to the "right" of the gear)

4mm is very

small..it would have to be a really tight

fit inside the new brass tube,

otherwise thats

going to be a wobbly wheelset.

B.

the other, much

better option is to simply use new axles! new machined axles of the proper

length.

the problem with

that idea is I have no way to make such axels myself..I dont have a lathe,

and I dont know

anyone locally who does.

A few guys on

the On2 forum have talked about the possibiity of machining axles and selling

them!

Which would be

great!

I started to attempt

"method A"..cutting the axels and using brass tubing.

but I couldnt

cut the axle!

my jewelers saw

barely made a dent in the hard steel..this might not be the best way to

go afterall.

So instead I emailed

John

Rogers, of Rogers Model Locomotive Works, who created the

first

reported On2 forney conversion, and asked him if he would be willing

to take on a Forney axle job..

He agreed! (thanks

John!) so I popped them in the mail.

John says: "Rogers

Model Locomotive Works will convert forney axels, do machining or a full

conversion.

I made the

jigs for my own models and this is my way of sharing them. I can

also supply new bottom plates

made from

PC board with new electrical pick ups."

I only had John

do the axels this time, and not the frame.. the price is very reasonable

IMO..

perhaps for future

conversions I will have him do the whole thing! because now I still have

to

grind down the

frame myself! I will attempt that when the drivers come back.

While the axels

are underway, I started work on the cab.

To

Page 3, the new cab. To

Page 3, the new cab.

Back

to Page 1 of SR&RL No.9 Back

to Page 1 of SR&RL No.9

Back

to my main page. Back

to my main page.

|