| Update,

March 14, 2006

I know

I said this update will *probably* be of the finished car..

well..it

isnt!

sorry..

but

its almost done!

New

end platforms had to be built.

I

used Grandt Line On3 end beams and railings.

Because

the G.L. parts are designed for 3-foot gauge cars, they are too

wide

for my 2-foot gauge car.

they

are 47mm wide and I need them to be 41mm wide.

simple

solution..chop out 6mm from the middle and glue them back together!

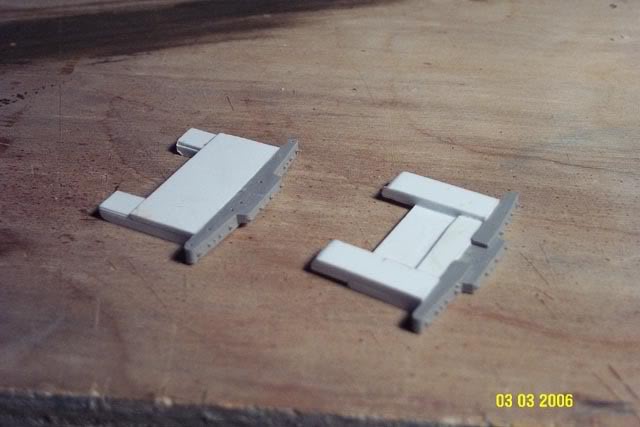

The

original, unmodified beam is on the top,

the

chopped one on the bottom:

Now

new end platforms have to built from styrene.

cut

two rectangles 14mm by 32mm by 1.5mm thick:

(I

only used the 1.5mm because I happened to have it, but its pretty close

to

what I needed..)

A few

more bits of styrene make up the finished platforms.

and

the G.L. end beams are glued on.

Left

platform is top view.

Right

platform is bottom view.

I use

Plastruct "plastic weld" for any plastic-to-plastic gluing.

super-glue

for anything else.

The

location of the trucks had to be moved inward a few mm from the prototype

position,

so they would clear the platform and still pivot properly.

On

the prototype, the trucks actually sit *between* the platform supports!

but

the curves of our model railroads always require some compromises..

this

is one of them.

I

doubt the difference will even be noticable.

they

are moved inward 6mm from where they "should" be..

If

I didnt tell you they were too far inside, I bet no one would have ever

noticed!

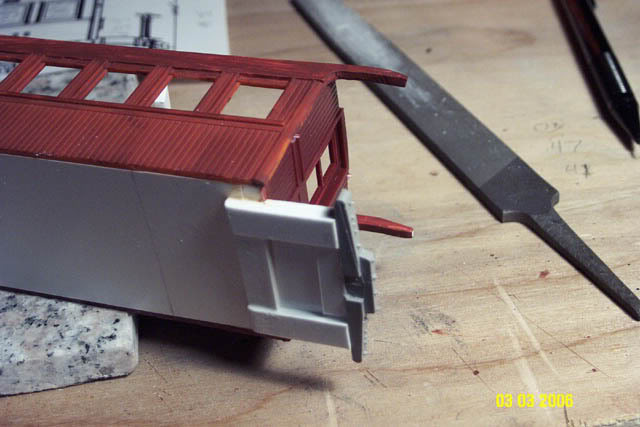

New

steps scratchbuilt from brass strips.

I

used brass rather than styrene so I could bend the step supports into an

"L" shape

to

hold the step itself.

I used

the Grandt platform handrails as-is.

the

opening in the center between the two sets of handrails ends up being a

bit

narrow,

because of the 6mm taken out of the center of the end beam, but I can live

with it!

again,

thats another example of "if you didnt know it was there, you probably

wouldnt

have

noticed"!

im

giving away too many flaws!

these

are all just tiny compromises we have to make to build an operating model.

no

model is ever 100% to scale anyway.

Since

I have no immediate use for the Bachman On30 trucks, I chopped off the

brakes

to

add to my new trucks! makes a big difference in apperance!

I

cut the brake shoes off of the Bachman trucks, built a brass strap connecting

the

brake shoes, and glued the assembly to the trucks.

original,

brakeless truck on the left.

new

truck, with brakes, on the right.

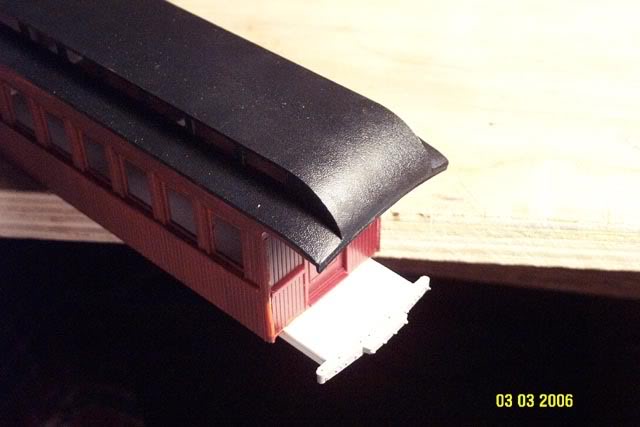

How

to attach the roof??

I

didnt want to glue the roof on..because the bolts for the trucks

extend up

into

the coach body, im going to add seats, the window "glass" might fall off

someday...having

a roof glued on is just asking for trouble..

Why

taunt Murphy??..you know he will make you pay for it!

you

*know* you are going to need to get back inside someday for something!

so..I

came up with a styrene "frame"..the outside dimension of the frame (37mm)

is exactly

the

same as the inside width of the coach body.

Then

the new styrene frame is firmly glued to the underside of the roof,

making

sure its all nice and centered.

Now

that frame slides down into the coach, and since the outside of the frame

is

the same width as the inside of the coach, and the coach walls naturally

bend

inward

a bit as well, the roof is held on quite tightly by pressure alone.

and

can be easily lifted off as necessary.

Painting

underway!

I used

Tamiya AS-13 Green (USAF) for the green of the coach body.

and

Floquil 130601 Zinc Chromate Primer for the roof.

both

are spray cans.

(the

Floquil Z.C. primer is an *exact* match to the Floquil Oxide Red in the

bottle)

Looks

good!

almost

done!

Ok,

the next update will *really* be of the finished car!

I

mean it this time!

On

to Page 5!

sscotsman@yahoo.com

Back

to Page 1 of the coach bash.

Back

to Scot's main page

|